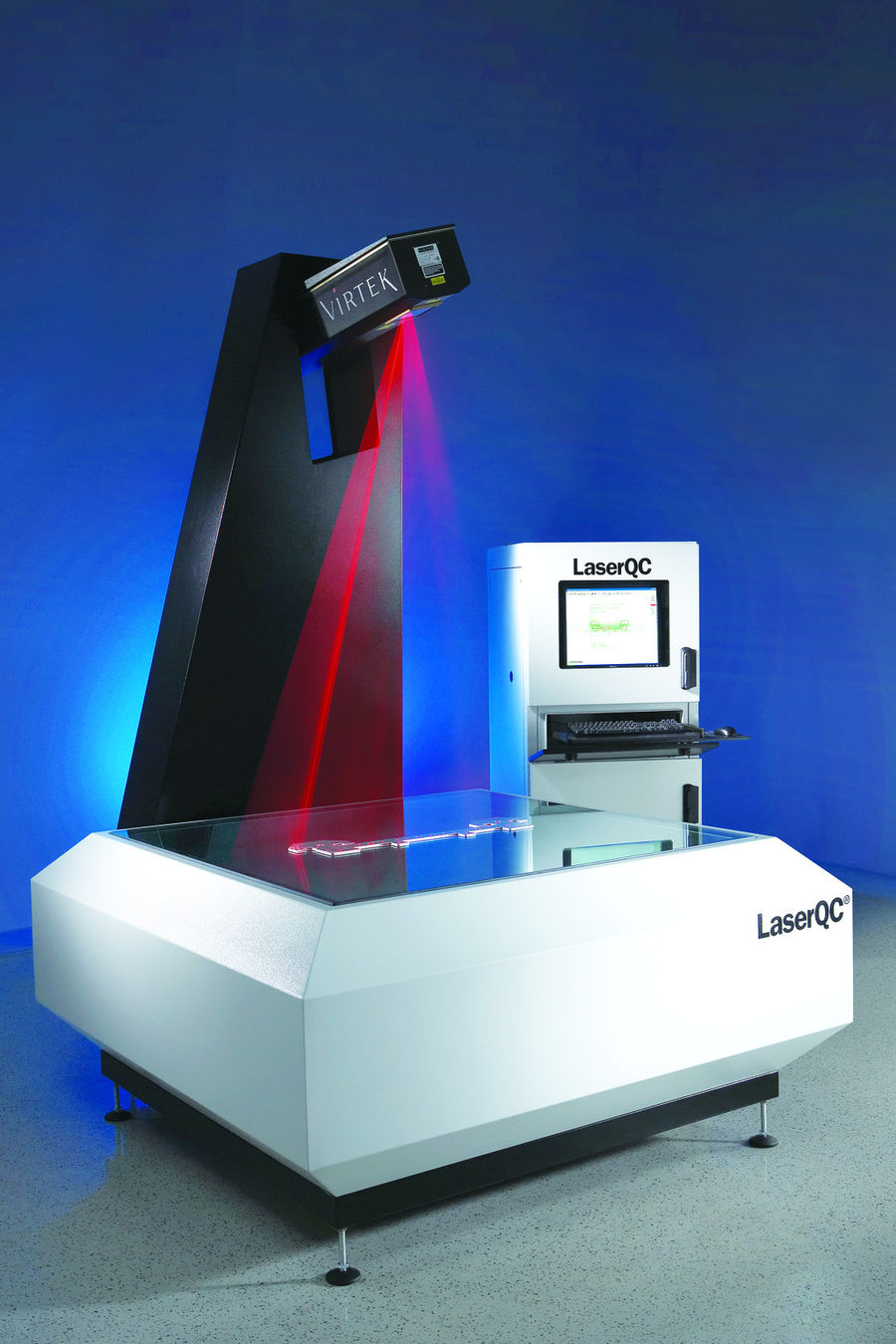

Virtek laserqc automatic form measurement afm is a rapid inspection system that employs lasers to measure the accuracy of three dimensional parts to tolerances within 0 25mm 0 010 inches.

Virtek laserqc afm.

Maximum part size single scan.

This site uses cookies.

Virtek vision international ulc is a market leader in laser projection and quality inspection systems improving productivity and reducing cost.

Enjoy the videos and music you love upload original content and share it all with friends family and the world on youtube.

Virtek laserqc afm is designed for easy set up so it can be operational in only a few hours.

Virtek laserqc afm captures more than 500 data points per second and is accurate to within 0 25mm 0 010 inches.

Virtek iris 3d with the new vision positioning system vps significantly advances laser guided assembly with innovative flashalign functionality and superior laser line visibility plus a flexible workstation with multi tasking and a new thin client architecture.

New laserqc automatic form measurement afm option the introduction of laserqc afm makes 3d measurement simple.

1220mm x 1220mm 48 x 48 scanning accuracy.

Laserqc self calibrates and adjusts system set tings to accommodate for environmental changes common to the shop floor.

0 05mm 0 002 in the flat and 0 25mm 0 010 for formed inspection.

Learn about the industries we serve throughout the globe.

Virtek laser qc system model 1200 afm.

Virtek laserqc afm is designed for easy set up so it can be operational in only a few hours.

Initial alignment is 20x faster and re alignments are reduced from minutes to seconds save time increase workflow all.

Virtek laserqc afm captures more than 500 data points per second and is accurate to within 0 25mm 0 010 inches.

In addition quality control reports instill customer confidence.

Laserqc offers a reliable low maintenance solution that operates along side your facilities cnc equipment.